In today’s dynamic publishing landscape, where market demand and stock risks remain unpredictable, an increasing number of publishers opt to print books only after they have been sold. Recognizing this, PrintForce, a prominent company based in the Netherlands, embraces its powerful motto, “Understanding Challenges,” by tailoring their printing prowess to the unique requirements of each client.

PrintForce, founded in 2004, has emerged as a leading player in the digital printing industry, specializing in single-copy minimum or stockless productions. With a steady growth trajectory over the years, the company has established its position as one of Europe’s largest digital printing companies. From its Dutch origins, PrintForce boasts an international clientele, reflecting its unique position in the market.

The company’s success stems from its unwavering commitment to an extremely efficient workflow and continuous investments in state-of-the-art printing, finishing and binding technologies. Through streamlined processes, PrintForce offers an array of services, including automated ordering, eWarehousing, flexible production, express logistics, and digital invoicing. These comprehensive solutions empower customers to reduce stock, save costs and minimize environmental impact, while meeting incredibly short time-to-market deadlines.

“When it comes to book production, PrintForce is dedicated to delivering the highest quality products, ensuring excellence in every aspect. We offer volumes up to 1500 units that we rapidly produce and make available to bookstores and online retailers within 24 hours. To make this possible, we deploy the latest technologies to enhance applications and drive down production costs” stated Rik Thijssen, Operations Manager at PrintForce.

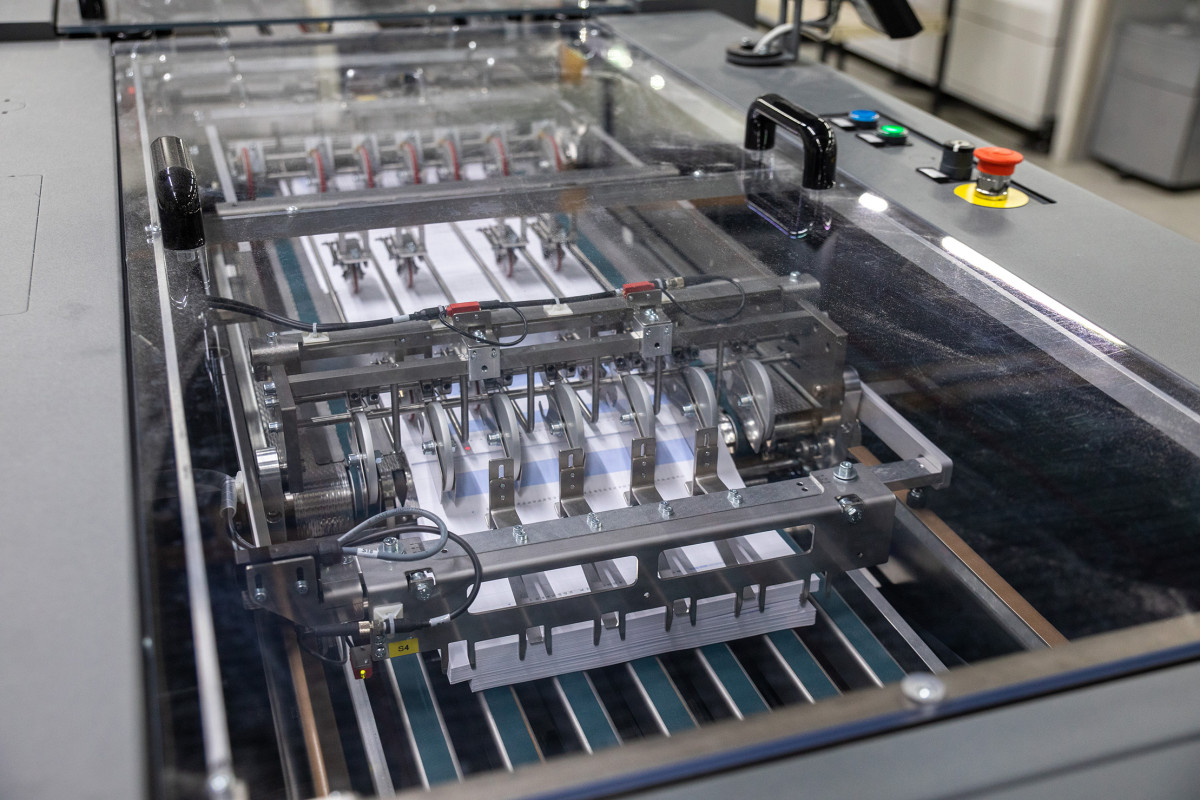

To increase the speed and reliability of their book production and mitigate stock risks for their customers, PrintForce invested in three Tecnau Stack 1010 cutsheet systems for cutting and stacking digitally printed applications inline to one Canon varioPRINT iX3200 and two Canon varioPRINT i300 sheetfed inkjet presses.

“The Tecnau Stack 1010 cutsheet systems, with their innovative features and technology, reduce labor by producing smaller, stacked finished pages in a single collated process. The solutions offer exceptional accuracy and consistency, ensuring perfectly aligned finished prints without requiring any offline guillotine cutting. The high-speed capabilities of the Stack 1010 make them ideal for demanding production environments, maximizing efficiency and matching the full speeds of digital presses,“ commented Harm Jan Hulleman, Sales Director EMEA at Tecnau.

The streamlined production workflow, facilitated by the Stack 1010 cutsheet solutions, minimizes operator involvement, creating neatly slit, cut, and stacked book-blocks inline with Canon varioPRINT sheetfed inkjet presses. The Stack 1010 systems run all the paper weights and sizes that sheetfed printers can handle while matching speeds and productivity.

Switching between impositions is a quick and straightforward process that requires minimum intervention: all adjustments for application changes are driven by the touchscreen display that guides the operator through the required steps with a visual reference to prevent errors and minimize waste.

Stack 1010s are equipped with the Tecnau Connect software control platform to supervise production, reduce failures and increase productivity. This system enables real-time monitoring and analysis of production and service data, optimizing processes and predicting maintenance needs. Tecnau Connect enhances productivity and status monitoring, contributing to a steady growth in Overall Equipment Effectiveness (OEE) and streamlined production.

PrintForce demonstrates a strong commitment to environmental sustainability by actively seeking ways to reduce waste, conserve energy, and promote eco-friendly practices throughout its operations. “The integration of Tecnau Stack 1010 solutions connected to our Canon varioPRINT sheetfed inkjet printing systems in our workflow has allowed us to highly automate lean book production with fast turnarounds, impeccable quality standards, reduced errors, and minimized waste“, added Rik Thijssen.

“PrintForce underwent a remarkable transformation after this integration. Prior to the Tecnau Stack 1010 installations, we were meticulously printing on the exact paper size for each book, whether it was A4 on A4+ or A5 on A5+ paper. This strict requirement stemmed from our commitment to meet customers’ demanding 24-hour delivery times, where any extra steps between printing and binding were impractical, including using offline guillotine cutting. Unfortunately, this approach decreased press productivity and potentially increased printing and material costs. Everything changed with the introduction of Stack 1010. We can now effortlessly print on larger sheets and cut to smaller sizes, resulting in a significant increase in our throughput while still maintaining our existing SLAs. This upgrade in workflow management not only enhanced our productivity but also ensured cost-efficiency in our printing operations with less paper types to be purchased and less paper wasted. The Canon varioPRINT presses now run more efficiently and we experience up to 50% more production capacity than before,” he concluded.

The installation of the three Stack 1010 solutions, integrated with the Canon varioPRINT presses at Printforce, was skillfully managed by Kentie-Rotaform, the local distributor of Tecnau in the Netherlands. “The exceptional coordination and expertise of all the technicians involved allowed for a seamless transition, as we programmed the installations in a way that ensured uninterrupted productivity by upgrading only one line at a time. This strategic approach guaranteed uninterrupted service to PrintForce’s customers throughout the entire upgrading process,” stated Michel Carlier, Manager Director at Kentie.

PrintForce’s dedication to efficiency, customer satisfaction, and environmental consciousness has positioned it as a leader in the digital printing industry not only in the Netherlands. The company is also present in the United Kingdom with a production facility in Biggleswade, where Tecnau continuous feed cut & stack solutions featuring the StreamFolder module have been implemented since the beginning.

By understanding the challenges faced by their customers and forging strong partnerships, PrintForce continues to provide innovative solutions while minimizing its environmental impact. With a diverse range of services and an unwavering focus on delivering high-quality products, PrintForce exemplifies the harmonious convergence of technology and sustainability in the ever-evolving landscape of digital printing.